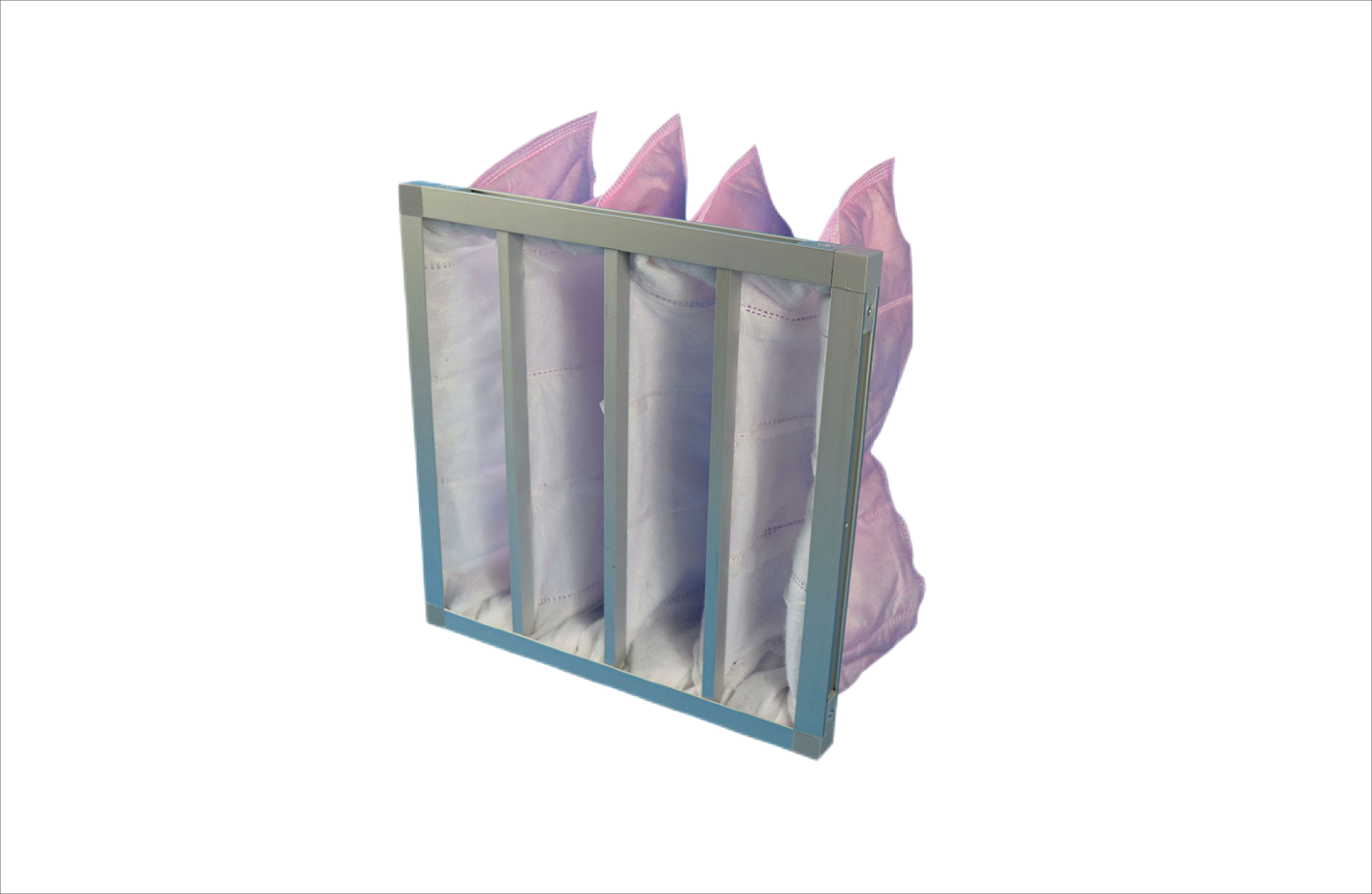

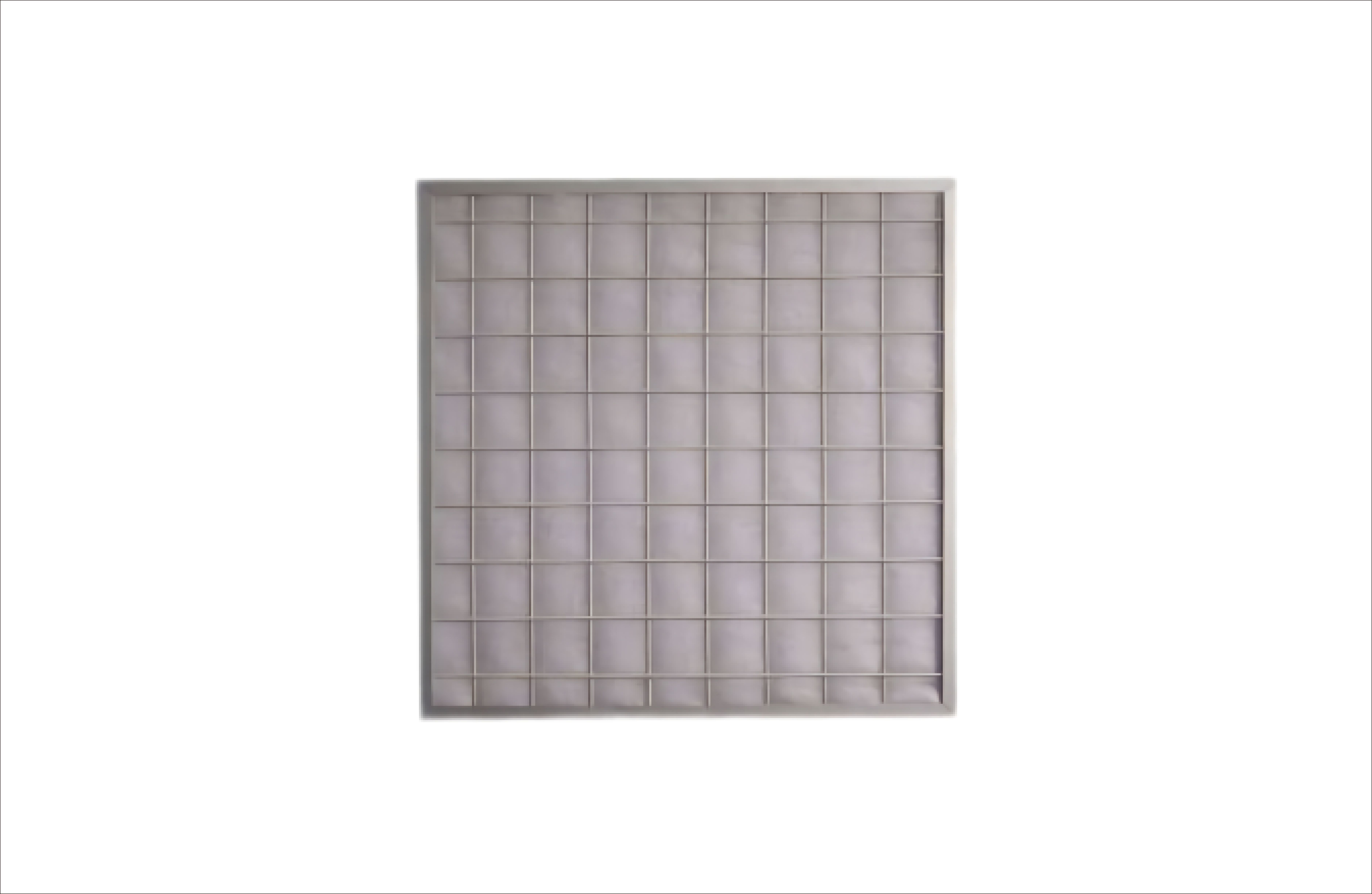

We have global top talents and comprehensive qualifications in design, decoration, electromechanical installation, steel structure, environmental protection, purification, etc. We specialize in providing cleanroom solutions for companies in the fields of semiconductor microelectronics, LED LCD display, optoelectronics, photovoltaic chips, precision machinery, food and drugs, biological laboratories, hospital operating rooms and aerospace. In addition to the cleanroom, environmental protection and intelligent system solutions, we also provide comprehensive EPC services involving engineering consulting, design, project management, construction and installation, operation and maintenance, and application for review and inspection.